A sign is so much more than a marker. It’s often the very first handshake between your business and the world, the silent ambassador that speaks volumes before you ever say a word. It’s the face of your brand. In a world of fleeting first impressions, custom metal signs stand apart as the premier choice for anyone looking to convey durability, elegance, and quality. They are vital elements of branding, wayfinding, and communication that leave a lasting impact.

This guide is your complete resource for understanding the world of metal signage. We will walk you through everything, from the basic question of “why metal?” to the science behind different materials. We’ll explore the professional fabrication process and even give you a corner for your own DIY projects. By the time you’re done, you’ll have the confidence to design, choose, or create a metal sign that truly represents your vision.

Table of Contents

Why Choose Metal? The Enduring Appeal of Metal Signage

When you have options like wood and plastic, what makes metal the superior choice for signage? The answer lies in a powerful combination of strength, beauty, and flexibility that other materials simply can’t match.

What Defines a Metal Sign?

At its core, a metal sign is any piece of signage crafted from a metal material, such as aluminum, steel, brass, or copper. These signs can be functional, like a street sign guiding traffic, or decorative, like a beautiful logo in a corporate lobby. They serve a single purpose: to communicate a message with strength and style.

The Core Advantages of Metal Over Other Materials

Let’s break down why metal signs have become the preferred choice for businesses and homeowners who value quality.

Unmatched Durability and Longevity

This is the most significant advantage. Metal is tough. Unlike wood that can rot and warp, or plastic that can grow brittle and fade in the sun, a well-made metal sign can endure the harshest conditions. Think about it:

- Weather Resistance: They stand strong against heavy rain, strong winds, and years of relentless sun exposure.

- Structural Integrity: Metal signs are far less likely to crack, warp, or fade over time.

- A Smart Investment: Because they last for decades, metal signs are an incredibly cost-effective choice. You invest once in a quality sign and avoid the recurring costs of replacing cheaper, less durable alternatives.

Unparalleled Aesthetic Flexibility

Don’t mistake strength for a lack of style. Metal signs offer an incredible range of looks to match any brand’s identity.

- Wide Range of Styles: You can achieve a sleek, modern feel with brushed aluminum or powder-coated steel. Or, you can evoke a timeless, elegant look with the classic appeal of bronze or brass.

- Custom Finishes and Textures: The possibilities are nearly endless. A sign can be polished to a mirror shine, given a rustic patina for a weathered look, or even hammered for an artisanal texture. This flexibility ensures your sign perfectly aligns with your brand.

Versatility in Application

Metal signs are the chameleons of the signage world. They fit in seamlessly just about anywhere.

- Outdoor Use: They are perfect for storefronts, address plaques, monument signs, and directional markers.

- Indoor Use: Inside, they bring a touch of class to lobbies, reception areas, conference rooms, and even home decor.

- Modular Designs: For businesses like retail stores or real estate offices where information changes frequently, modular metal signs are a practical solution. These signs feature interchangeable components, allowing for easy updates without replacing the entire sign.

A Professional Image: The high-end appearance of metal instantly communicates professionalism and a commitment to quality. When customers see a solid metal sign, they perceive the business as reliable, trustworthy, and attentive to detail.

The Foundation—A Deep Dive into Metal Sign Materials

The “metal” in metal signs isn’t just one thing. The type of metal you choose will dramatically impact your sign’s appearance, durability, and cost. Understanding these materials is the first step to creating the perfect sign for your needs.

Choosing the Right Metal: A Comparison

Here’s a detailed look at the most common metals used in sign making. We’ve compiled their key characteristics to help you decide which one is right for your project.

| Material | Key Characteristics | Best For | Appearance |

|---|---|---|---|

| Aluminum | Lightweight, affordable, highly resistant to rust and corrosion, easy to cut and shape. | The most popular all-around choice for both indoor and outdoor signs. Great for storefronts, real estate, and wayfinding. | Sleek and modern. Can be brushed for a matte look, polished, or powder-coated in any color. |

| Stainless Steel | Extremely strong, durable, and resistant to corrosion. Heavier and more premium than aluminum. | High-end, professional signage where a modern, sophisticated look is crucial. Corporate lobbies, luxury brands. | Clean, contemporary, and professional. Often seen with a brushed or polished finish. |

| Corten Steel | Also known as “weathering steel.” It is designed to develop a stable, protective layer of rust over time. | Outdoor applications where a rustic, industrial, or artistic look is desired. Parks, rustic brands, architectural features. | A unique, deep-orange, weathered patina that evolves over time. |

| Brass & Bronze | These classic metals offer a timeless, elegant, and sophisticated look. They are heavier and more expensive. | Plaques, historical markers, commemorative signs, and luxury businesses like law firms or high-end hotels. | Brass has a warm, golden tone. Bronze has a richer, deeper brown hue. Both develop a beautiful natural patina with age. |

| Copper | Known for its unique warm, reddish-brown tone. It is a softer metal that is highly prized for its appearance. | Boutique shops, high-end restaurants, and decorative pieces where a warm, antique look is desired. | Starts with a bright, penny-like shine and develops a stunning greenish-blue patina over time. |

| Zinc | Offers a unique grayish-blue tone and has excellent natural resistance to corrosion. | Custom signage for vintage or industrial-styled decor, especially in damp environments. | A subtle, matte, grayish finish that is both modern and understated. |

Metal Composites: The Best of Both Worlds

Sometimes, the best solution involves combining materials. Metal composite panels are engineered to be lightweight yet strong, making them a practical choice for certain applications.

- Alumalite: This material features a corrugated (wavy) plastic core sandwiched between two thin sheets of aluminum. It’s incredibly lightweight but rigid, making it a great choice for larger signs like post and panel or real estate signs.

- Dibond: Similar to Alumalite, Dibond has a solid plastic core between two aluminum sheets. It’s known for being very flat and stable, making it ideal for printing high-quality graphics for yard signs, real estate signs, and other custom applications.

Specialty Steels for Niche Uses

While less common for general signage, some projects require even tougher materials.

- Abrasion Resistant Steel (e.g., AR500): This is an extremely hard and tough steel known for its resistance to wear. You won’t use it for a storefront, but its properties make it the perfect material for high-intensity uses like shooting targets.

From Vision to Reality: The Professional Design & Fabrication Process

A great metal sign doesn’t just happen. It’s the result of a careful, collaborative process that combines artistic vision with precision engineering. Here’s a look at how a professional sign company brings your idea to life.

The Design Journey: A Collaborative Process

The foundation of any great sign is a great design. This phase is crucial and typically involves several steps to ensure the final product is exactly what you envisioned.

Step 1: Initial Consultation

This is where it all begins. You’ll sit down with the sign company to discuss your vision, brand identity, and goals. A good company will also assess the intended location, considering factors like visibility, viewing distance, and environmental conditions that could affect the sign.

Step 2: Digital Design & Rendering

Skilled designers take your ideas and use advanced software (like CAD programs) to create detailed digital proofs or renderings of the proposed sign. This allows you to see what your sign will look like before it’s made. This phase often involves a few rounds of revisions to fine-tune the colors, fonts, and layout until it’s perfect.

Step 3: Key Design Principles for Impact

Pro Tip: When designing signage, less is often more. A simple, concise message with bold visuals captures attention much more effectively than a cluttered sign with too much information.

To create an effective sign, designers focus on a few core principles:

- Layout: The content—text and graphics—must be organized in a clear, coherent way. A good designer will group essential information to deliver a compelling message without unnecessary clutter.

- Typography: The font style and size are critical for legibility. This is especially true for metal signs that use engraving or embossing. The text needs to be clear and easy to read from the intended viewing distance.

- Color & Contrast: High contrast between the background and the text is key to readability. A sign with low contrast will be difficult to understand, especially from afar. It’s also important to consider how a glossy metal finish might create glare in different lighting conditions.

Precision Fabrication Techniques Explained

Once the design is approved, it’s time to make the sign. This is where high-tech machinery and skilled craftsmanship come together. The techniques used will depend on the metal, the design’s complexity, and the desired finish.

| Fabrication Technique | How It Works | Best For |

|---|---|---|

| Laser Cutting | A highly concentrated laser beam melts or vaporizes the metal, creating incredibly precise and clean cuts. | Intricate designs, detailed logos, and complex letter shapes with sharp, clean edges. |

| Waterjet Cutting | A high-pressure stream of water mixed with an abrasive material (like garnet) cuts through the metal. | Cutting very thick metals without creating heat-affected zones, resulting in a smooth, burr-free edge. |

| Plasma Cutting | A jet of hot, ionized gas (plasma) melts the metal, which is then blown away. It’s faster than laser cutting but less precise. | Thicker metals and simpler shapes where extreme precision is not the top priority. Common in industrial settings and DIY projects. |

| CNC Machining | A computer-controlled machine uses various cutting tools to precisely shape, route, or drill the metal. | Creating 3D shapes, beveled edges, and ensuring exact dimensions across multiple pieces. |

Shaping and Assembly

For signs with depth, several other techniques are used:

- Welding: For signs made of multiple components, welding is used to join the pieces into a single, cohesive structure.

- Bending and Forming: Metal benders and other tools are used to create curves and angles, giving the sign a three-dimensional shape.

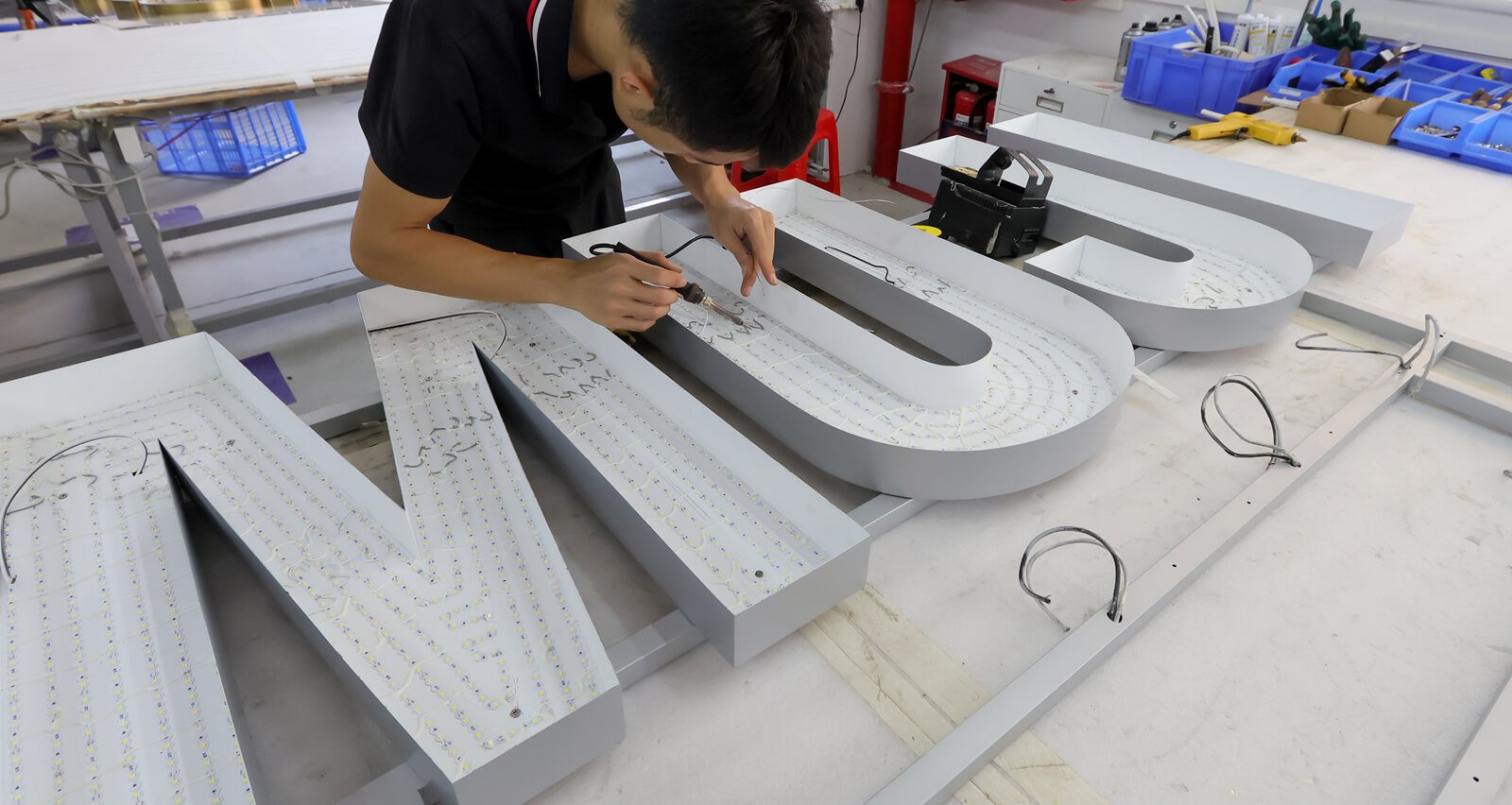

- Creating Dimensional and Channel Letters: These iconic 3D letters are built by cutting the face (front), return (side), and back separately, then carefully assembling them.

Adding Detail and Text

- Engraving: This technique involves physically carving text or logos into the metal’s surface for a classic, permanent look.

- Embossing: This process uses heat and pressure to stamp a design onto sheet metal, creating a raised (3D) texture.

- Etching: A more delicate method that uses acid or lasers to create fine, detailed designs on the surface of the metal.

The Final Touch: Finishes for Protection and Aesthetics

The final step is applying a finish. This not only determines the sign’s final look but also protects it from the elements.

- Powder Coating: This is one of the most durable finishes available. A dry powder is applied to the metal and then cured with heat, creating a thick, hard finish that is much tougher than conventional paint. It is UV-protected and available in virtually any color.

- Anodizing: Used for aluminum, this is an electrochemical process that creates a very hard, corrosion-resistant, and decorative layer on the surface.

- Painting: High-quality, industrial-grade paints, including eco-friendly water-based options, can be used. Enamel spray paint is a good choice for signs that won’t face harsh weather.

- Polished vs. Brushed: A sign can be polished to a mirror-like shine for a brilliant, eye-catching look, or brushed to create a soft, satin-like matte texture for understated elegance.

- Raw or Natural Finish: Sometimes, the best finish is no finish at all. Raw steel or Corten steel signs are left untreated to develop a natural, rustic patina over time.

The DIY Corner: Crafting Your Own Metal Sign

Feeling creative? Making your own metal sign can be an incredibly rewarding project. It gives you complete creative control and can be a fun way to learn a new skill. However, it’s a project that requires the right tools, a focus on safety, and a bit of patience. This section combines the best tips from experts to guide you on your DIY journey.

Should You DIY? The Pros and Cons

Before you start, it’s important to decide if a DIY project is right for you.

- Pros: You get total control over the design, it can be more cost-effective if you already have some tools, and it’s a fulfilling hobby that results in a unique, personalized piece.

- Cons: It requires specialized (and potentially expensive) tools, there are significant safety risks involved with cutting metal, and it can be challenging to achieve a truly professional-looking finish without experience.

Your DIY Toolkit: Essential Materials and Safety Gear

Gathering your supplies beforehand will make the process much smoother. Here’s what you’ll need.

Materials:

- Metal Sheet: For beginners, a sheet of aluminum is a great choice because it’s lightweight and easy to cut.

- Design Template: You can sketch your design on paper or print it out from a computer.

- Stencils and Markers: To accurately trace your design onto the metal.

Tools:

- Metal Cutting Tool: A jigsaw with a metal-cutting blade is an affordable option for simple cuts. For more complex shapes, a plasma cutter is ideal but is a more significant investment.

- Drill with Metal Bits: For creating mounting holes.

- Files and Sandpaper: For smoothing sharp edges after cutting. This is a crucial step!

- A Deburring Tool: A specialized tool to safely remove the rough, sharp edge (burr) left after cutting.

Safety Gear (This is non-negotiable!):

- Safety Goggles: To protect your eyes from flying metal particles.

- Heavy-Duty Gloves: To protect your hands from sharp edges and hot metal.

- Ear Protection: Especially when using loud power tools like a plasma cutter.

- Dust Mask: To avoid inhaling metal dust.

- A Well-Ventilated Workspace: To clear away any fumes.

- Fire Extinguisher: Cutting metal can create sparks, so always have one nearby.

A Step-by-Step Guide to Your First Homemade Metal Sign

Ready to get started? Follow these steps for a successful project.

- Design and Plan: Finalize your design. Keep it simple for your first project. Think about the size, shape, and any text or patterns.

- Transfer the Design: Place your template on the metal sheet and secure it with tape. Carefully trace the outline with a marker.

- Cut the Metal: Securely clamp the metal sheet to a sturdy work surface so it can’t move. Put on all your safety gear. Using your jigsaw or plasma cutter, slowly and carefully follow the lines you marked.

- Smooth the Edges: This step is critical for safety and a professional look. After cutting, the edges will be very sharp. Use a file and sandpaper to smooth every edge until it’s no longer sharp to the touch.

- Paint and Finish: Clean the metal surface thoroughly with a mild detergent to remove any oils or dirt. Once dry, apply a layer of metal primer. After the primer dries, apply your chosen paint (spray paint works well for an even coat). You may need several coats. Let it dry completely, then apply a final clear coat sealant to protect the paint and prevent rust.

When to Get Help from a Professional

While DIY is fun, some things are best left to the pros. If your design is highly complex, features an intricate logo, or if you need a very large sign, partnering with a professional sign maker is the best way to ensure a high-quality, durable, and perfectly finished product. They have the advanced tools and experience to bring even the most ambitious visions to life.

A Typology of Metal Signs: Exploring Different Forms and Styles

The term “metal sign” covers a vast array of styles, each with a unique look and purpose. Understanding these different types will help you choose the one that best fits your brand and space. Let’s explore the most common forms of metal signage.

Flat and Cutout Signs

These are some of the most common and versatile sign types, built from flat sheets of metal.

- Flat-Cut Metal Letters & Logos: These are solid, individual letters or logo shapes precision-cut from a single sheet of metal. They are then mounted directly onto a wall or other surface, offering a clean, classic, and elegant look.

- Metal Cutout Signs (Negative Space): In this style, the design is created by cutting the letters or shapes *out* of the metal panel, leaving behind negative space. This creates a modern, stencil-like effect that can be very striking, especially when placed over a contrasting background.

Three-Dimensional (3D) Signage

For signs that truly pop, 3D construction adds depth, shadow, and a powerful sense of permanence.

- Fabricated Metal Letters: These are not solid; they are hollow 3D letters constructed like a box. The face (front) and returns (sides) are cut and welded together. This method allows for large, deep letters that are surprisingly lightweight.

- Cast Metal Letters: For a more substantial, premium feel, cast letters are made by pouring molten metal (like aluminum or bronze) into a custom mold. The result is a solid, heavy, and highly detailed letter with a classic, authoritative look.

- Dimensional Signs: These are multi-layered signs where different components are stacked on top of each other. This creates compelling depth and shadow effects, making the sign visually dynamic.

Illuminated Metal Signs: Lighting Up Your Brand

Adding light to a metal sign transforms it from a daytime marker into a 24/7 beacon for your brand. Illumination dramatically increases visibility and creates a sophisticated, eye-catching effect.

| Illumination Type | Description | Effect |

|---|---|---|

| Backlit (Halo-Lit) | LEDs are mounted on the back of the letters or sign, pointing toward the wall. | Creates a beautiful, soft glow or “halo” around the sign, making it appear to float off the wall. Very elegant and modern. |

| Face-Lit | The front face of the fabricated letter is made from a translucent material (like acrylic), with LEDs placed inside. | The light shines directly through the front of the letters, creating a bright, bold, and highly visible sign. This is the classic “lit sign” look. |

| Edge-Lit | Lighting is focused just along the edges of the letters. | Produces a sleek, subtle outline of light that highlights the shape of the sign. Very contemporary and stylish. |

| Marquee Letters | A vintage style that features exposed light bulbs on the face of the letters. | Evokes a classic, retro, or theatrical feel. Creates a warm and inviting ambiance. |

Common Signage Formats

These sign types are often defined by how and where they are installed.

- Monument Signs: These are low-profile, freestanding signs often found at the entrance to a corporate campus, neighborhood, or shopping center. They are typically made of materials like concrete, brick, or stone, with metal letters or logos integrated into the design.

- Pylon Signs: These are the tall, freestanding signs you see from the highway, often featuring multiple business names on a single structure. Their height is designed for maximum visibility from a long distance.

- Hanging Signs: A classic storefront look, these signs are suspended from a decorative bracket attached to the building’s facade.

- Plaques: Usually smaller, plaques are used for professional identification (like for a doctor or lawyer), historical markers, awards, or memorials. Brass and bronze are very popular choices for plaques.

Installation and Maintenance: Protecting Your Investment

Your beautiful new metal sign is ready. Now what? Proper installation is key to ensuring your sign looks great and stays secure for years to come. And with just a little bit of care, you can keep it looking pristine.

Professional vs. DIY Installation

While it might be tempting to install a sign yourself to save money, it’s not always the best idea. You should strongly consider hiring a professional installer if:

- The sign is large or heavy.

- The sign is illuminated and requires electrical wiring.

- It needs to be installed high up on a building.

- You are mounting it on a difficult surface like brick, stone, or tile.

A professional will have the right tools (like a bucket truck), experience, and insurance to get the job done safely and correctly.

How to Hang Your Metal Sign: A Surface-by-Surface Guide

If you’re installing a smaller, manageable sign yourself, the method you use will depend entirely on the wall surface.

Safety First: Before drilling into any wall, always check for electrical wires or pipes behind the surface.

- Drywall: This is the most common indoor surface. Use a stud finder to locate a wooden stud in the wall and screw directly into it for the most secure hold. If there’s no stud where you want to hang the sign, you’ll need to use drywall anchors. Simply drill a pilot hole, insert the anchor, and then drive your screw into the anchor.

- Brick, Stone, or Concrete: These surfaces require more power. You will need a hammer drill and a masonry drill bit. You can then use specialized screws like Tapcon screws, which are designed to thread directly into masonry, or use sleeve anchors for a secure hold.

- Wood: This is the easiest surface to work with. Simply use wood screws of an appropriate length to secure your sign.

- Tile: This is the trickiest surface, as tile can easily crack. For lightweight signs, the best no-drill option is a high-strength, waterproof double-sided tape, like 3M VHB (Very High Bond) tape. If you must drill, it’s highly recommended to hire a professional.

- Vinyl Siding: For a no-drill option, you can use vinyl siding hooks or clips that slip under the siding panels. If you need a more secure hold for a heavier sign, you must screw into the structural sheathing (like plywood) *behind* the siding, not just into the thin vinyl itself.

Mounting Techniques for Different Effects

How you mount the sign also affects its final look.

- Flush Mount: The sign is installed directly against the wall. This creates a clean, flat, and seamless appearance.

- Standoff / Pin Mount: This is a very popular technique where small metal barrels or “standoffs” are used as spacers between the sign and the wall. This makes the sign “float” a short distance off the surface, creating attractive shadows and giving it a dimensional, high-end look.

Long-Term Care and Maintenance

The good news is that metal signs require very little maintenance. To keep yours looking its best:

- Cleaning: For general dust and grime, simply use a soft microfiber cloth, warm water, and a mild soap. Gently wipe the sign clean and blot it dry. Never use abrasive scrub pads or harsh chemical cleaners, as they can damage the finish.

- Repairing Scratches: For very light surface scratches, you may be able to minimize their appearance by applying a small amount of car wax to the area and buffing it with a soft cloth.

- Rust Prevention: Most sign metals like aluminum and stainless steel are naturally rust-resistant. If you have a sign made of carbon steel, it should have a protective finish like powder coating. If that finish gets chipped, it’s a good idea to touch it up to prevent rust from forming. For Corten steel, remember that the rust is a natural, protective layer and should be left alone.

The Business of Signage: Strategy, Cost, and Compliance

For a business, a sign is a critical marketing tool. Its design and placement should be a strategic decision, not an afterthought. This section covers the key business considerations, from branding and budget to legal compliance.

Aligning Signage with Brand Identity

Your sign is a physical representation of your brand. It must be consistent with your company’s identity.

- Consistency is Key: For businesses with multiple locations, it is crucial to use the same logos, fonts, and color schemes across all signs. This builds a strong, recognizable brand image that customers can instantly identify.

- Communicate Your Values: The style of your sign says a lot about you. A sleek, minimalist stainless steel sign might convey innovation and modernity, while a classic bronze plaque could suggest tradition and reliability. Make sure the look of your sign matches the message you want to send.

Budgeting for a Custom Metal Sign: What Influences the Cost?

The price of a custom metal sign can vary widely. Understanding the factors that influence the cost will help you create a sign that fits your budget.

| Cost Factor | Impact on Price |

|---|---|

| Size | Larger signs require more material and labor, so they cost more. |

| Material | Aluminum is generally the most economical choice. Premium metals like brass, bronze, and copper are more expensive. |

| Thickness (Gauge) | Thicker metal is more durable but also costs more. |

| Complexity | An intricate, multi-layered design with fine details will cost more than a simple, flat-cut sign. |

| Finish | A standard powder coat is a common option. More complex or premium finishes can add to the cost. |

| Illumination | Adding LED lighting (backlit, face-lit, etc.) will significantly increase the cost due to the materials and electrical work involved. |

The ROI of Quality Signage

It’s important to view your sign not as an expense, but as a long-term investment. A high-quality, well-designed sign works for your business 24 hours a day, 7 days a week. It can:

- Increase Foot Traffic: An eye-catching sign attracts more customers off the street.

- Enhance Brand Perception: A professional sign makes your business look more credible and successful.

- Provide Lasting Value: Because of their durability, metal signs don’t need to be replaced often, saving you money in the long run.

Navigating Regulations: Permits and ADA Compliance

Before you install a new outdoor sign, you need to do your homework. Many areas have specific rules you must follow.

- Sign Permits: Most cities and towns require a permit for new outdoor business signs. This process ensures your sign meets local codes for size, placement, and safety. You may also need approval from your local Homeowners’ Association (HOA) or property management company. A professional sign company can often help guide you through the permit process.

- ADA Compliance: The Americans with Disabilities Act (ADA) sets requirements for certain types of signs to ensure they are accessible to everyone, including people with visual impairments. For signs that identify permanent rooms or spaces, ADA compliance is often required. Key requirements include:

- A non-glare finish.

- High contrast between the text and the background.

- Specific, easy-to-read fonts.

- Raised tactile letters and Braille.

The Future of Metal Signage

The world of signage is constantly evolving. While the classic appeal of metal is timeless, new technologies and trends are expanding the possibilities of what a sign can be.

Integration with Technology

- Smart Signage: We’re beginning to see signs that can display real-time, interactive content. Imagine a restaurant sign that automatically updates with daily specials or a retail sign that interacts with a customer’s smartphone.

- 3D Printing: This technology is making it possible to create incredibly complex and customized metal shapes that would be difficult or impossible with traditional fabrication methods.

- Augmented Reality (AR): In the near future, you might point your phone at a metal sign to trigger an interactive 3D model or a video, creating an immersive brand experience.

Sustainability in Signage

As environmental awareness grows, so does the focus on eco-friendly practices in the sign industry.

- Recycled Materials: Metals like aluminum and steel are highly recyclable. Many new signs are made from recycled content, and old signs can be recycled at the end of their lifespan.

- Durability as a Green Choice: The very longevity of metal signs is a sustainable feature. A sign that lasts for decades reduces waste and conserves the resources needed to create replacements.

- Eco-Friendly Practices: Many sign companies are adopting more sustainable practices, such as using energy-efficient LED lighting, low-waste manufacturing processes, and environmentally friendly paints.

Frequently Asked Questions (FAQ)

Here are quick answers to some of the most common questions about metal signs.

- What is the best metal for outdoor signs?

- For most outdoor applications, aluminum is the best choice due to its excellent balance of durability, light weight, and affordability. It is naturally resistant to rust. For a more premium, high-end look, stainless steel is also a fantastic and highly durable option.

- How long do metal signs last?

- The lifespan depends on the material and conditions, but you can generally expect a well-made outdoor metal sign to last 5 to 10 years or even longer. Indoor metal signs can last for decades.

- How thick should my outdoor sign be?

- The thickness, or gauge, depends on the size of the sign and how windy the location is. For general outdoor signs, a thickness of .063 inches is often sufficient. For larger signs or those in very harsh environments, a thicker gauge like .125 inches is recommended for added rigidity.

- Will my metal sign rust?

- It depends on the metal. Aluminum and stainless steel are highly resistant to rust. Carbon steel, however, will rust if its protective coating (like paint or powder coat) is scratched off. Corten steel is a special case—it is *designed* to form a protective layer of rust.

- What is the difference between powder coating and painting?

- Powder coating is a more durable finish. It involves applying a dry powder to the metal, which is then cured with heat. This fuses the coating to the metal, creating a finish that is much harder and more resistant to chipping and scratching than conventional liquid paint.

- Can I put a high-resolution photo on a metal sign?

- Yes! Through modern techniques like digital printing, it is possible to print vibrant, high-resolution images and graphics directly onto a metal surface.

Conclusion: Make Your Statement in Metal

From a simple address plaque to a grand, illuminated storefront logo, custom metal signs offer an unmatched combination of durability, beauty, and versatility. They are far more than just markers; they are a powerful statement about your brand’s commitment to quality and a wise investment in its long-term success. The strength of metal ensures your message endures, while its aesthetic flexibility allows you to craft an identity that is uniquely yours.

Whether you’re a creative homeowner embarking on a DIY project or a business owner ready to elevate your brand’s presence, you now have the knowledge to move forward with confidence. The world of metal signage is vast, but its principles are clear: quality materials, thoughtful design, and precision craftsmanship lead to a result that stands the test of time.

Ready to bring your vision to life? We encourage you to reach out to a reputable, quality-focused sign company. Their expertise will be invaluable in transforming your ideas into a stunning, durable metal sign that truly represents you and your brand for years to come. Find a custom sign expert near you today!